ThermEvolve Technology

Control: the secret behind reliable engine heating systems.

We're not the first to try, just the first to succeed. How to heat engine components reliably has been an open question for decades, and it's only become more urgent with the introduction of freeze-prone emission-control components in EPA Tier III regulations (EU Phase 3). Previous attempts at heating engine components have hit problem after problem – but ThermEvolve technology solves all of them. Here's how:

- No overheating: The simplest component heaters are a simple, uncontrolled heating element, stuck directly on the component. To work in the coldest conditions, these heaters have to produce enough heat to overheat during normal conditions – leading to fire and melting hazards. ThermEvolve limits the heater's temperature to a temperature safe for everything it's in contact with.

- No underheating: Another common solution is a self-limiting heater, with an inherent top-out temperature. Those who use these in practice, though, find that the heating performance is uneven, unreliable, or underpowered. ThermEvolve systems use full-power heaters that can reliably – and safely – produce all the heat necessary.

- No controller burnout: Temperature control, which is needed to solve the two problems above, is nothing new – thermostats have been around for over 100 years – but temperature control on an engine battery's DC supply consistently fries conventional mechanical thermostats. The result: frequent maintenance and costly downtime. ThermEvolve uses SoliStat™, a proprietary, burnout-resistant thermostat that on average lasts well over 5 million switch cycles – as opposed to conventional thermostats' five to ten thousand.

- No excessive power drain: Solutions without power control often end up constantly drawing high wattage. ThermEvolve technology sips power and saves it for engine startup, where it's needed most.

- Fast heat-up: Unlike uncontrolled systems, ThermEvolve technology can safely deliver heat to the component as fast as it's capable of absorbing it. Systems powered with ThermEvolve usually reach operating temperature in 5 minutes or less.

- Dependable in any weather: Many conventional thermostats are rated to work only as low as 32°F (0°C), which makes them unusable for freeze prevention. ThermEvolve systems perform at temperatures as low as −40°F (−40°C), eliminating worries about the cold.

Put ThermEvolve Technology in Your Engine

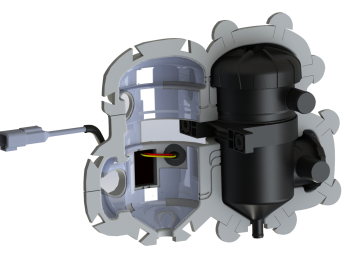

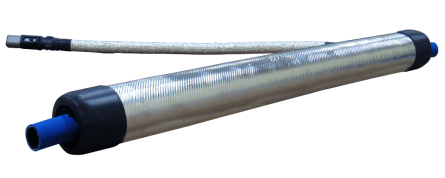

ThermEvolve technology is at the core of our IntelliHose and IntelliThaw product lines:

We've also combined IntelliThaw and IntelliHose to make integrated, complete heating systems. Read more about these custom solutions. >>

Get in touch with a distributor today to discuss a ThermEvolve solution that will work in your engine.

More on ThermEvolve

Options and subsystems available

Any system based on ThermEvolve technology can be ordered with any of these options and subsystems:

- Bypass mode – allows the jacket to be powered off completely during idle periods.

- System ready and system fault lights – check for system problems at a glance.

- Fusing and crowbar circuit – automatically power down the system in case of a fault or a severe disruption.

- Multiple channels – power multiple heaters, or a heater and cooler, with one controller.

Download a printable product document

engenity, ThermEvolve Flyer, Rev B4.pdf

Adobe Acrobat document [940.1 KB]