Application Notes and FAQ

This page serves as the application notes for the SoliStat™ as well as the IntelliHose® and IntelliThaw® product lines, all of which use ThermEvolve® technology for optimum heat control.

What is a Solidstat?

Uh, that’s SoliStat™.

OK, so what is it?

SoliStat is an industrial-grade, tamper-proof thermostat for direct-current-powered heating and cooling applications. You can use it to control heaters, fans, pumps, or anything else that draws a

fair bit of current and needs to be switched on or off in response to temperature changes.

So, how do I use a SoliStat? It’s got a lot of wires.

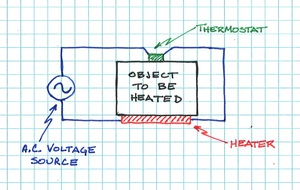

Granted, it’s not a two-terminal bi-metal thermostat. Figure 1 is a mechanical representation of a traditional minimal heating system—you’ve got the object to be heated, the thermostat, the heater,

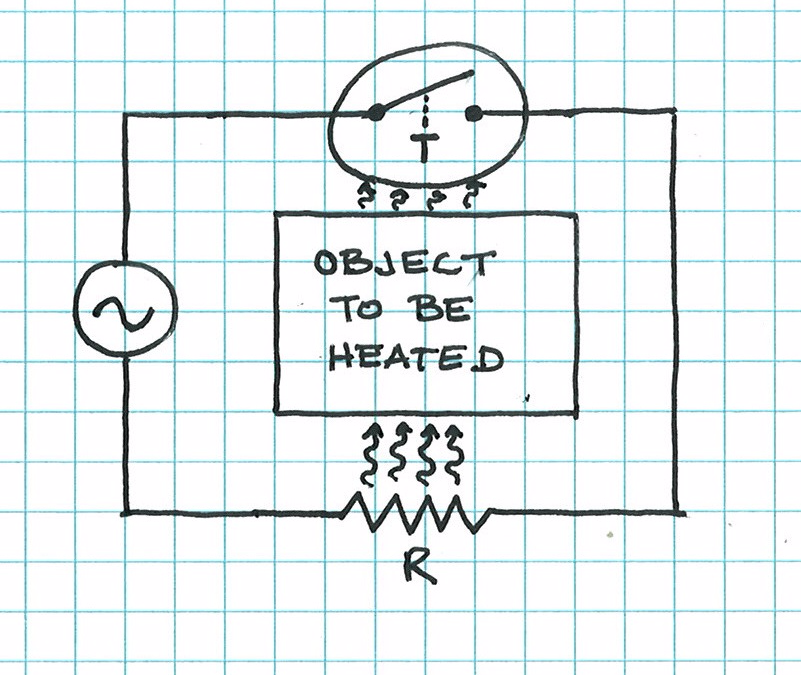

and the voltage source. We’re showing the voltage source as A.C., because we don’t recommend using a two-terminal bi-metal thermostat in D.C. applications. Figure 2 is an electrical schematic

representation of the same thing.

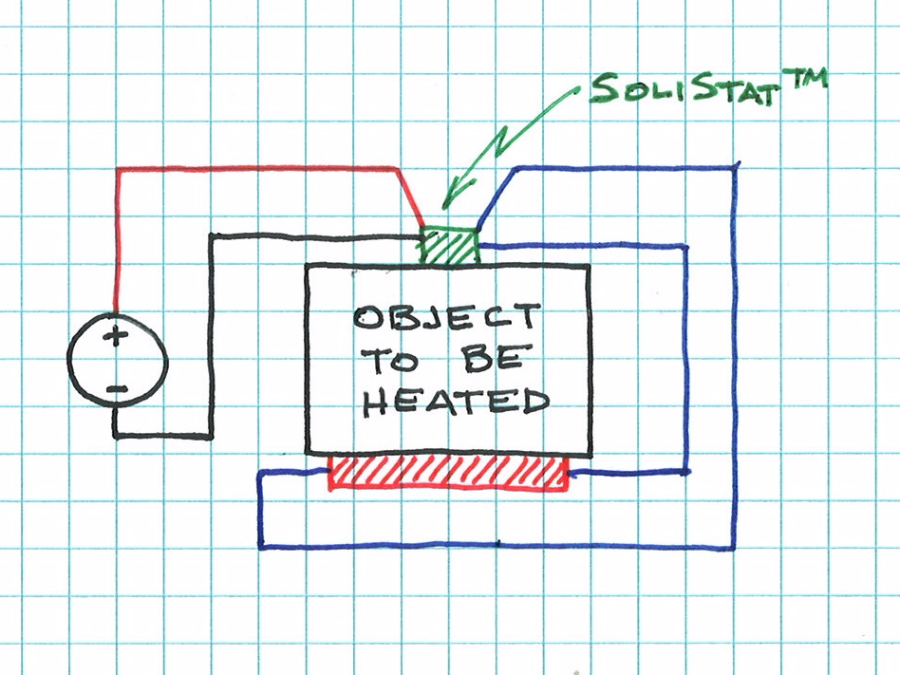

Figure 3 is a mechanical representation of a minimal heating system, but here, we have replaced the bi-metal thermostat with a SoliStat, and the A.C. voltage source has been replaced with a D.C. voltage source. Note that the SoliStat’s red wire connects to the source’s positive terminal and the SoliStat’s black wire connects to the source’s negative terminal. The two white wires (represented in blue on Figure 3) connect to the heater.

Figs. 1–3. Click an image to enlarge.

But one of the white wires has a stripe on it. Is there something special about that?

Read the answer below.

OK, but I’m connecting to a pump, and unlike a heater, its connections are polarity sensitive. What am I supposed to do?

Ah, right… good question. The short answer is; it depends on which SoliStat model you have.

SoliStat 2-10, SoliStat 2D-5, SoliStat 2X-15, and SoliStat 2XD-10 all use what’s known as a high-side switch. This means that power to the heater, pump, fan, or whatever is connected and interrupted by a switch that is in line with the POSITIVE terminal of the voltage source. These models have a white wire with a black stripe, which is a direct connection through the SoliStat to the negative terminal of the voltage source; the solid white wire is the switched positive voltage.

SoliStat 2-20 and SoliStat 2X-30 both use what’s known as a low-side switch. This means that power to the heater, pump, fan, or whatever is connected and interrupted by a switch that is in line with the NEGATIVE terminal of the voltage source. These models have a white wire with a red stripe, which is a direct connection through the SoliStat to the positive terminal of the voltage source; the solid white wire is the switched negative voltage.

Fine, but my SoliStat has six wires; four that are the same heavy gauge and two that are a lighter gauge. What’s that all about?

The Green 20AWG wire is the System Bypass line and the Black 20AWG wire is internally connected to the voltage source’s negative terminal. Connecting the Green wire to 0V (through a switch, relay, or

logic signal) will prevent the SoliStat from operating. Connecting the Green wire to any voltage greater than 1.5V, and up to your system’s supply voltage, will put SoliStat back in operating

mode.

Why would I want to put SoliStat into bypass mode anyway?

There are a couple of situations that we’ve seen where you’d want to do that.

First, let’s say you’re using SoliStat to control a heater in a piece of construction equipment that gets used ten hours a day Monday through Friday. You’ve got a big enough battery in the equipment

that if SoliStat keeps running the heater overnight during the weeknights, there’s still enough cranking Amps left in the battery in the morning to start the equipment. But, if SoliStat keeps running

the heater over the weekend, when you show up on Monday morning the battery’s dead. So you wire up a switch to connect the bypass line to 0V.

The other situation is where you’ve added SoliStat and a heater as a fix to a cold-weather-related problem that showed up in the field. The heater current you need is enough that if the heater’s on when everything else in the system is on, the total load demand exceeds what the system is capable of providing. So, in this type of situation, you simply set up your engine control unit to send a low level to the bypass line during those periods when the heater can’t be switched on.

SoliStat is rated for voltages from 6 – 24V, but my actual system voltage is 28V, is that going to be a problem?

No, it won’t be. SoliStat’s internal circuitry will withstand continuous voltages even a bit higher than 28V. Also, there’s quite a bit of internal circuitry that provides a high level of immunity to

transients.

So, does that mean that SoliStat HV-20 can withstand continuous voltages a bit higher than 48V?

Yes.

72V maybe?

No. For that, you’ll need the SoliStat XHV, which is currently under development. If you’re interested, you’ll need to contact us directly or

through one of our distributors.

Is SoliStat used in ThermEvolve® products?

We use SoliStat 2XD-10 in a couple of different IntelliHose® models. Other ThermEvolve products use circuitry and algorithms that are based on

SoliStat’s.

Do you offer any standard ThermEvolve products?

Yes, we do. We currently (as of June, 2016) offer IntelliThaw® heating jackets for MotoRad’s

MO-75 crankcase breather cap (it may fit other manufacturers’ cross-referenced parts) and Mann+Hummel’s ProVent 200 crankcase ventilator

filter. We will be offering IntelliThaw heating jackets for Mann+Hummel’s ProVent 400 and a crankcase ventilator filter manufactured by Donaldson for John Deere (JD P/N RE544804). We should point out

that we developed and are developing these IntelliThaw heating jackets independently and at the request of equipment users who have experienced cold-weather-related problems with the aforementioned

components.

What about standard IntelliHose products?

Currently, we offer three models of IntelliHose for a few different Case bulldozer models.

So, I’m not an O.E.M, but I’ve got a few pieces of equipment that give me problems during the winter months. What can you do for me?

For starters, all of the aforementioned standard products are available from our distributors.

OK. Well, it looks like you’ve got my ventilator filter covered, but I’ve got a breather hose that gives me fits too. Am I out of luck on that?

Nope, not at all. The great thing about IntelliHose heated hoses is that we can manufacture them in small quantities (yes, even a single piece) fairly quickly. Get in touch with your distributor and

tell them the details of the hose you’re trying to heat, and they will get you a quote. Bear in mind that if you have a hose that you know gives you problems, the time to get a quote for an

IntelliHose replacement is between March and the end of July. By late August we’re starting to get busy, and after that we’re usually slammed through winter. So, during that time (late August through

early March) you might have to wait a couple of weeks for a quote, and an IntelliHose that we could have gotten out the door in two days in July might have a four week lead time in November.

But what if I’m not an O.E.M. and I’ve got a part that gives me problems when the weather gets cold? Is there anything you can do for me?

Maybe. First, talk to one of our distributors. They may be able to help you solve your problem using SoliStat and one of the heaters they sell. If your cold-weather-related problem can’t be solved

that way, we may consider making an IntelliThaw heating jacket for it. The distributor will forward all of the pertinent information to us, we will consider your application, and the distributor will

let you know whether we’ve decided to work on it.

If I want an IntelliThaw heating jacket, how long will it take before I can get first articles for testing?

If you have 3D models (native SolidWorks preferred, STEP files acceptable) we can make testable hand-built prototypes in as little as two weeks (lead time depends on part complexity and time of

year). Molded parts can be made in as little as eight weeks (depends on part size and time of year).

How much power do IntelliThaw heating jackets and IntelliHose heated hoses consume?

That depends on a number of factors. The IntelliThaw MO-75 consumes 60W at startup; the IntelliThaw PV200 consumes 190W at startup. After the temperature inside the heating jacket gets up to the

desired setpoint, average power consumption drops to a fraction of that. The IntelliHose heated DEF hoses consume 200W on startup, and again, average power consumption drops to a fraction of that

after things are warmed up.

Why do they consume that much power?

Because the customers who asked us to design those products gave us the following parameters:

- Starting temperature: –40˚F

- Time to reach operating temperature: 5 minutes or less

There were no restrictions on current draw.

You say that once the desired setpoint is achieved the average power consumption drops to a fraction of the startup power consumption. How does that work, and what, exactly do you mean by

average power consumption?

The SoliStat-based control that is used in IntelliThaw heating jackets and IntelliHose heated hoses uses what is known in the world of process heating as ON/OFF control. That means that when the

temperature inside the jacket or hose drops below the desired setpoint the control switches the heater on. Once the temperature reaches the desired setpoint, the control switches the heater off. How

frequently the heater is switched on and off, and how long the heater will be on is entirely dependent on the ambient temperature.

So, whenever the heater is on, it is consuming the maximum power – e.g., 190W for the IntelliThaw PV200. But, if you look at the power consumption over time – let’s say over an hour – you’ll see that the heater is off for a lot of that time. If you take the average of the power consumption over that time, you’ll see that it is quite low – e.g., for the IntelliThaw PV200, again after the setpoint has been reached, average power consumption is about 4W at –10˚C, 8W at –30˚C, and 10W at –50˚C. We have a lot of test data that we’d be happy to share with you if you contact us.

Well, if the average power consumption is as low as you say, why did you make the maximum power consumption so high?

Because that was the amount of power that was required to achieve the setpoint temperature given the customer’s requirements (see above). The power required to maintain the setpoint temperature is

considerably less. This is almost always true when heating any object or process.

Speaking of power consumption, do all IntelliHoses consume 200W?

No. These standard hoses were designed for a power level of 10W per foot of hose. In the case of these hoses, this power level allows us to completely thaw DEF, starting from –40˚F, in about

three-and-a-half minutes. IntelliHoses designed for crankcase ventilation applications generally perform well at this power level too, although we are currently working on a proprietary ventilator

hose that, at the customer’s request, consumes 60W per foot.

What? I’ve put heaters that powerful on ventilator hoses before and I charred them… made a heck of a mess. I don’t think you can do that.

Well, you can do it if you’re using our patent-pending ThermEvolve technology.

Do I need to re-program my engine control unit to use IntelliThaw heating jackets or IntelliHose heated hoses?

No. They are designed to operate autonomously. Just connect them to your equipment’s power source—switched or un-switched, that’s your decision.

Well, if I’m using IntelliThaw or IntelliHose how do I know when it’s up to the setpoint temperature?

For starters, if we do a proprietary design for you, you’ll get a pile of test data from us that will give you an idea of how long it takes to achieve the setpoint. That said, we offer, as an option,

a SETPOINT READY line that can be connected to an engine control unit, a relay, or an LED.

OK. Do you offer any other options in the way of communicating how IntelliThaw or IntelliHose are working, or controlling them externally?

Yes, we do. We offer a SYSTEM BYPASS line; same as with SoliStat. There is a TEST MODE/ALTERNATE SETPOINT line, which raises the setpoint to a temperature that will activate the heater during summer

temperatures so that you can verify operation without an ambient temperature that will freeze your fingers. There’s also a SYSTEM ERROR output that can be connected to an engine control unit or an

LED.

More Information – Printable PDFs

ThermEvolve Technical Function, Rev C.pd[...]

Adobe Acrobat document [168.7 KB]